| Steinbauer Project! The BMW 635 CSI |

14 October 2012: Changed out the fan belt and power steering belt since I was driving on borrowed time. The

power steering belt was not in such bad shape like the fan belt but it did not hurt at 241,625 miles on the clock.

While I was out there I thought I fix my stuttering windshield wipers. Right below you see the old baked on and

hardened grease! I took some carburetor cleaner and cleaned it up. Then I took some fresh grease and lubricated

the whole mess again but making sure that the plate and the contacts remained free of grease. No big deal? I'd say

it is since now, even with a dry windshield the interval setting works like a charm!

power steering belt was not in such bad shape like the fan belt but it did not hurt at 241,625 miles on the clock.

While I was out there I thought I fix my stuttering windshield wipers. Right below you see the old baked on and

hardened grease! I took some carburetor cleaner and cleaned it up. Then I took some fresh grease and lubricated

the whole mess again but making sure that the plate and the contacts remained free of grease. No big deal? I'd say

it is since now, even with a dry windshield the interval setting works like a charm!

26 Mar 2013: Wow, it really has been that long since I did something on the car aside from putting a radio in. Today

was an emergency fix when the fan belt broke. Shame since I just replaced that one 6,000 miles ago. What made it

sort of unpleasant was the fact that it was on the way to work, 10 F, and still dark. I had to get the jack and lift Fritz up

a bit since there was not enough room for me to get under there.

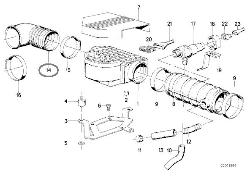

27 Apr 2013: Did an oil, oil filter, and air filter change at 248,200 miles.

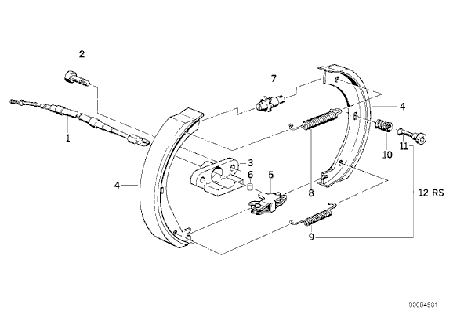

4 May 2013: Developed a real ugly squeaking and suspected the rear wheel bearing on the passenger side. Upon

further investigation it turned out that the pin (No 11 in the picture) worked its way out and caused the ugly squealing

along with part number 11. That was a cheap fix, no new parts involved. Lesson learned and applied - Investigate

first and then order parts.

was an emergency fix when the fan belt broke. Shame since I just replaced that one 6,000 miles ago. What made it

sort of unpleasant was the fact that it was on the way to work, 10 F, and still dark. I had to get the jack and lift Fritz up

a bit since there was not enough room for me to get under there.

27 Apr 2013: Did an oil, oil filter, and air filter change at 248,200 miles.

4 May 2013: Developed a real ugly squeaking and suspected the rear wheel bearing on the passenger side. Upon

further investigation it turned out that the pin (No 11 in the picture) worked its way out and caused the ugly squealing

along with part number 11. That was a cheap fix, no new parts involved. Lesson learned and applied - Investigate

first and then order parts.

11 May 2013: Replaced the distributor and rotor at 248,500 Miles. Discovered that the shaft seal in the upper timing

case is leaking oil into the distributor cap causing the car to run rough. Part is ordered and will be put in as soon as

possible following the same procedure as I did with Heidi

18 May 2013: What a waste of time today! Tried to replace the seal and the engine mount. I was thrilled to discover

that I could remove the seal from the upper timing chain housing without removing the housing in itself. Messed up

when I put the new seal in since it went to far and it fell through. Made a holy mess in the engine compartment when

the oil sprayed all over the engine compartment. I got the seal back out but while it was wrapped around the camshaft

it got damaged. I contacted Rick to see if his work happened to have one. He had the seal that he was planning on

installing in Elise but did not need to after all. Just my luck, he had it in his tool box and nobody was at work anymore

on a Saturday. Had no choice but to put the old one back in. No local part store had the part. O'Reiley said they did

but it turned out the be the crankshaft seal and not the camshaft seal. Easy to confuse. The only good part of this

day in regards to the car was that I discovered that the valve cover breather hose was damaged. Applied some

silicone to the cracks since I don't have those just laying around until I can get a new one.

23 May 2013: Why do we always assume that the ignition wires are ok? I have been reading several posts on Big

Coupe were people have hesitation, rough idle, etc but nobody came up with faulty ignition plugs. Until me today. Car

ran very crappy and rough. Checked all sorts of things starting with the distributor cap and rotor, to the spark plugs, to

the relays, to the sensors, checking all hoses at the air intake, the ignition coil, and as a final straw I thought I check

the ignition wires and sure enough they were faulty. Switched them out and I have a smooth idle and great

acceleration. Just thought I throw that in here real quick, I still have to swap out the camshaft seal at the upper timing

chain housing since it is still spraying some oil in there but other than that, no complaints.

25 May 2013: Took the car up to Denver where Rick did an alignment, We have now 249,500 miles on that car and it

ran perfect up and down from Denver. As I got back, I put the new seal into the upper timing chain cover. Hope I don't

have to go there in the future.

01 June 2013: Installed a motor mount on the passenger side since the old one was cracked. Also installed a new

valve cover breathing hose. That was desperately needed, the old one was hard and cracked. In the process I

noticed that a bolt at the exhaust manifold was lose and one was missing! I was wondering why I did smell exhaust

fumes. All fixed now and Fritz runs so well, if I would not already own that car I would buy it!

08 June 2013: There was some more exhaust fumes coming into the cabin and the exhaust manifold needed some

more tightening, Had that pin in the parking brake come out again and put that back in but this time pulled the spring

a little bit longer. We'll see how this holds up now. Finally figured out why the windshield washer pump was not

working. The main power cable came off but the plug to the main pump and the high intensive washer pump each

had 2 cables. A check in the schematics showed that there was a third cable which I found and attached.

case is leaking oil into the distributor cap causing the car to run rough. Part is ordered and will be put in as soon as

possible following the same procedure as I did with Heidi

18 May 2013: What a waste of time today! Tried to replace the seal and the engine mount. I was thrilled to discover

that I could remove the seal from the upper timing chain housing without removing the housing in itself. Messed up

when I put the new seal in since it went to far and it fell through. Made a holy mess in the engine compartment when

the oil sprayed all over the engine compartment. I got the seal back out but while it was wrapped around the camshaft

it got damaged. I contacted Rick to see if his work happened to have one. He had the seal that he was planning on

installing in Elise but did not need to after all. Just my luck, he had it in his tool box and nobody was at work anymore

on a Saturday. Had no choice but to put the old one back in. No local part store had the part. O'Reiley said they did

but it turned out the be the crankshaft seal and not the camshaft seal. Easy to confuse. The only good part of this

day in regards to the car was that I discovered that the valve cover breather hose was damaged. Applied some

silicone to the cracks since I don't have those just laying around until I can get a new one.

23 May 2013: Why do we always assume that the ignition wires are ok? I have been reading several posts on Big

Coupe were people have hesitation, rough idle, etc but nobody came up with faulty ignition plugs. Until me today. Car

ran very crappy and rough. Checked all sorts of things starting with the distributor cap and rotor, to the spark plugs, to

the relays, to the sensors, checking all hoses at the air intake, the ignition coil, and as a final straw I thought I check

the ignition wires and sure enough they were faulty. Switched them out and I have a smooth idle and great

acceleration. Just thought I throw that in here real quick, I still have to swap out the camshaft seal at the upper timing

chain housing since it is still spraying some oil in there but other than that, no complaints.

25 May 2013: Took the car up to Denver where Rick did an alignment, We have now 249,500 miles on that car and it

ran perfect up and down from Denver. As I got back, I put the new seal into the upper timing chain cover. Hope I don't

have to go there in the future.

01 June 2013: Installed a motor mount on the passenger side since the old one was cracked. Also installed a new

valve cover breathing hose. That was desperately needed, the old one was hard and cracked. In the process I

noticed that a bolt at the exhaust manifold was lose and one was missing! I was wondering why I did smell exhaust

fumes. All fixed now and Fritz runs so well, if I would not already own that car I would buy it!

08 June 2013: There was some more exhaust fumes coming into the cabin and the exhaust manifold needed some

more tightening, Had that pin in the parking brake come out again and put that back in but this time pulled the spring

a little bit longer. We'll see how this holds up now. Finally figured out why the windshield washer pump was not

working. The main power cable came off but the plug to the main pump and the high intensive washer pump each

had 2 cables. A check in the schematics showed that there was a third cable which I found and attached.

16 August 2013. Last night on my way home I heard a bang and then a series of what sounded like misfires. Good thing I was

close to home so I actually made it. Left the engine idle when I got in the garage and listened under the hood and accelerated

and heard the most awful noise which let me quickly turn off the engine. Attached picture shows what I found this morning.

Why a blessing in disguise? Well, the starter has been giving me a hard time so that is going to be fixed while the head is off.

The valve stem gaskets let me leave a cloud of smoke every now and then and that will be fixed also. Among all this I also get to

change out a few leaking gaskets around the front. All in all, the bad part is that it happened 2 weeks too early since I still have

to weeks of work before I get laid off.

17 August 2013: I pulled the spare engine out from under the shelf in the garage and took the head off and got it ready to take

it to the machine shop to have it checked. I did not think that there would be anything wrong with it but who knows? I also

wanted to have the valve stem seals replaced since I got tired of puffing smoke every, or almost every time I started going at a

red light. Not fair to all the motorists.

20 August 2013: After calling around and getting horrible quotes where the machine shops wanted to do work on that head

without even seeing it, I decided I'll take my engine head to Geddes after all. I thought that since the head should be treated

right before it gets installed and asked for a valve job. The man gave me a quote of anywhere between $300 and $500. Now

given the fact that I just got laid off, I hesitated with a valve job. Checking our finances decided to go for it after all and Geddes

told me that I really do not need one. I thought that was very nice since they could have done it or not done it and cash in the

money for it. Geddes even waited for me to bring the new valve stem seals before they put the head back together.

23 August 2013: Picked up the head and was pleasantly surprised that it was very nice and clean and the valve lash was

adjusted already. I will redo the adjustment after it has been running and well lubricated.

24 August 2013: Putting it all together and Murphy rears his ugly head again! What do I expect? Kris went and got me some

gasket glue and liquid gasket which I forgot to buy before I started. I tool the old head off without making a big mess since this

time around I took compressed air and blew out the system. Problems started with the starter! Man, I would hate taking that

stupid piece of equipment out with the head in place! I actually needed one of the tools that can be found in the trunk of a 6er!

Put the parts from the old head onto the new one and then had to go and get the parts off to replace the lower timing chain cover

This required removing the alternator, disconnect the power steering pump, and the harmonic balancer. Last but not least, the

feared 36 mm nut on the crank shaft (number 5 in the picture). That requires 350 Ft/lbs to open. Last time I did that i beasted 2

breaker bars to death with my bare hands! I bought a torque wrench to do the job but this time it did not work this way.

Remembering my mechanical engineer days I knew that it could be opened if I heat it up. OK, but where is my torch? Oh yeah,

that's right! I lent it to someone in the spring to fix their sprinkler system and I just did not get it back yet. So I had to call in an

emergency favor. In the meantime Robert went to get me a breaker bar with a 3/4 inch drive. There was nothing I could do at

this particular moment but wait. I got the torch and heated that nut but no luck! I walked around the house and came across

some skate board pipe that Mike left in the side yard. Heated that nut up again and used that steel pipe as an extension to get

that nut off! Worked!!! Then I noticed that the gasket from the oil pan (number 2 in the picture) is falling apart. After Kris

arrived with the liquid gasket I started putting things back together. The timing chain was caught off the sprocket and I had to

take the lower timing chain housing off again and fix that mess! As you may have guessed by now, the day is over and my back

is killing me.

25 August 2013: The reassembling of the car continues. Murphy made sure that I have a hard time connecting the exhaust

manifolds. The nuts there are 12 mm but they are copper and a 12 mm wrench is not an exact fit. A couple of them are really

hard to get to with the head is on the engine. Took me the rest of the day to put it all back together. The great moment came

when I started the engine! The valves made a horrible sound but that could have been the fact that they were dry. After letting

it run for about 10 minutes, I determined that this was not the case! Yes, the timing was off! Take the engine apart again

(Radiator out, alternator out, power steering pump disconnected, air flow assembly removed, valve cover, upper timing chain

and lower timing chain housing covers removed.

26 and 27 August 2013: I could dedicate a few hours every day to get it all together. Was so worn out on the night of 27

August that I did not want to start the engine up. I saved that for the next day.

28 August 2013: In case you are wondering why I waited till today with starting up the engine, it's because of the torque angel

for the head bolts. When installing the head, you have to follow a sequence of steps: step 1 : torque to 45 ft-lbs . Step 2 (wait

fifteen minutes) : torque to 60 ft-lbs. Step 3: Put everything back together and run engine for about 20-25 minutest where

engine will be at operating temperature): then turn a further 35 degrees with a torque angel meter. (do not get the one from

Autozone since I bought that piece and it does not work!) The tightening sequence is from the middle of the head outwards to

the front/rear of the head. Made sure that the bolt holes in the block are free of any oil or dirt otherwise tightening the head bolts

may crack the block. I may have tightened it more since I had no choice but to guess the angel.

29 August 2013: Took the car for a drive to my last day of work to Schriever AFB and it ran well even though my cable for

cylinder #5 is broken (connector on spark plug does no longer lock in and it just sits there causing rough idle). Working on that

next along with rechecking the valve lash.

5 October 2013: Hard to believe that two years have gone by and it was time again to replace the Drive shaft center support

bearing. No problem at all when I pulled the front part of the drive shaft off and removed the bearing. Not like I have never done

that before. Problem came when I tried to put that front part in line with the rear part (has to be aligned since that shaft is

balanced that way). I wound up having no other choice but remove the rear part of the drive shaft as well. I could tell that this

part has never been off since installing since the parts were fused together. There is not a lot of room under a car so it was

hard to get them apart. Took me 5 hours to get the entire thing out and back together but since I have no other work, I don't

mind.

close to home so I actually made it. Left the engine idle when I got in the garage and listened under the hood and accelerated

and heard the most awful noise which let me quickly turn off the engine. Attached picture shows what I found this morning.

Why a blessing in disguise? Well, the starter has been giving me a hard time so that is going to be fixed while the head is off.

The valve stem gaskets let me leave a cloud of smoke every now and then and that will be fixed also. Among all this I also get to

change out a few leaking gaskets around the front. All in all, the bad part is that it happened 2 weeks too early since I still have

to weeks of work before I get laid off.

17 August 2013: I pulled the spare engine out from under the shelf in the garage and took the head off and got it ready to take

it to the machine shop to have it checked. I did not think that there would be anything wrong with it but who knows? I also

wanted to have the valve stem seals replaced since I got tired of puffing smoke every, or almost every time I started going at a

red light. Not fair to all the motorists.

20 August 2013: After calling around and getting horrible quotes where the machine shops wanted to do work on that head

without even seeing it, I decided I'll take my engine head to Geddes after all. I thought that since the head should be treated

right before it gets installed and asked for a valve job. The man gave me a quote of anywhere between $300 and $500. Now

given the fact that I just got laid off, I hesitated with a valve job. Checking our finances decided to go for it after all and Geddes

told me that I really do not need one. I thought that was very nice since they could have done it or not done it and cash in the

money for it. Geddes even waited for me to bring the new valve stem seals before they put the head back together.

23 August 2013: Picked up the head and was pleasantly surprised that it was very nice and clean and the valve lash was

adjusted already. I will redo the adjustment after it has been running and well lubricated.

24 August 2013: Putting it all together and Murphy rears his ugly head again! What do I expect? Kris went and got me some

gasket glue and liquid gasket which I forgot to buy before I started. I tool the old head off without making a big mess since this

time around I took compressed air and blew out the system. Problems started with the starter! Man, I would hate taking that

stupid piece of equipment out with the head in place! I actually needed one of the tools that can be found in the trunk of a 6er!

Put the parts from the old head onto the new one and then had to go and get the parts off to replace the lower timing chain cover

This required removing the alternator, disconnect the power steering pump, and the harmonic balancer. Last but not least, the

feared 36 mm nut on the crank shaft (number 5 in the picture). That requires 350 Ft/lbs to open. Last time I did that i beasted 2

breaker bars to death with my bare hands! I bought a torque wrench to do the job but this time it did not work this way.

Remembering my mechanical engineer days I knew that it could be opened if I heat it up. OK, but where is my torch? Oh yeah,

that's right! I lent it to someone in the spring to fix their sprinkler system and I just did not get it back yet. So I had to call in an

emergency favor. In the meantime Robert went to get me a breaker bar with a 3/4 inch drive. There was nothing I could do at

this particular moment but wait. I got the torch and heated that nut but no luck! I walked around the house and came across

some skate board pipe that Mike left in the side yard. Heated that nut up again and used that steel pipe as an extension to get

that nut off! Worked!!! Then I noticed that the gasket from the oil pan (number 2 in the picture) is falling apart. After Kris

arrived with the liquid gasket I started putting things back together. The timing chain was caught off the sprocket and I had to

take the lower timing chain housing off again and fix that mess! As you may have guessed by now, the day is over and my back

is killing me.

25 August 2013: The reassembling of the car continues. Murphy made sure that I have a hard time connecting the exhaust

manifolds. The nuts there are 12 mm but they are copper and a 12 mm wrench is not an exact fit. A couple of them are really

hard to get to with the head is on the engine. Took me the rest of the day to put it all back together. The great moment came

when I started the engine! The valves made a horrible sound but that could have been the fact that they were dry. After letting

it run for about 10 minutes, I determined that this was not the case! Yes, the timing was off! Take the engine apart again

(Radiator out, alternator out, power steering pump disconnected, air flow assembly removed, valve cover, upper timing chain

and lower timing chain housing covers removed.

26 and 27 August 2013: I could dedicate a few hours every day to get it all together. Was so worn out on the night of 27

August that I did not want to start the engine up. I saved that for the next day.

28 August 2013: In case you are wondering why I waited till today with starting up the engine, it's because of the torque angel

for the head bolts. When installing the head, you have to follow a sequence of steps: step 1 : torque to 45 ft-lbs . Step 2 (wait

fifteen minutes) : torque to 60 ft-lbs. Step 3: Put everything back together and run engine for about 20-25 minutest where

engine will be at operating temperature): then turn a further 35 degrees with a torque angel meter. (do not get the one from

Autozone since I bought that piece and it does not work!) The tightening sequence is from the middle of the head outwards to

the front/rear of the head. Made sure that the bolt holes in the block are free of any oil or dirt otherwise tightening the head bolts

may crack the block. I may have tightened it more since I had no choice but to guess the angel.

29 August 2013: Took the car for a drive to my last day of work to Schriever AFB and it ran well even though my cable for

cylinder #5 is broken (connector on spark plug does no longer lock in and it just sits there causing rough idle). Working on that

next along with rechecking the valve lash.

5 October 2013: Hard to believe that two years have gone by and it was time again to replace the Drive shaft center support

bearing. No problem at all when I pulled the front part of the drive shaft off and removed the bearing. Not like I have never done

that before. Problem came when I tried to put that front part in line with the rear part (has to be aligned since that shaft is

balanced that way). I wound up having no other choice but remove the rear part of the drive shaft as well. I could tell that this

part has never been off since installing since the parts were fused together. There is not a lot of room under a car so it was

hard to get them apart. Took me 5 hours to get the entire thing out and back together but since I have no other work, I don't

mind.

14 February 2014: You know your wife loves you if she gets you the new world bumper signal lenses for Valentines day! For

some reason, Fritz did not seem to like that and I would up having all sorts of electrical issues. Funny part was that when all

was done, light bulbs were swapped out it was all fine again. I did try to cut the inner reflectors to size but that seemed

senseless if you can just go and take them out and paint the inside of the shell silver. I got that idea from Tom Schultz

some reason, Fritz did not seem to like that and I would up having all sorts of electrical issues. Funny part was that when all

was done, light bulbs were swapped out it was all fine again. I did try to cut the inner reflectors to size but that seemed

senseless if you can just go and take them out and paint the inside of the shell silver. I got that idea from Tom Schultz

Below you can see the difference between the "New World Signal Lenses" and the "Elephant Ears"

15 February 2014: Someone should say I don't have any foresight! I bought a brake light switch 5 years ago and actually got to

install it today. The old one was getting stuck and hence the brake lights would not work anymore. Now it is all working and I can

step on my brakes without worrying about someone rear ending me especially since I drive to work at night lately.

install it today. The old one was getting stuck and hence the brake lights would not work anymore. Now it is all working and I can

step on my brakes without worrying about someone rear ending me especially since I drive to work at night lately.

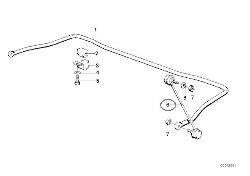

03 March 2014: Installed new stabilizer links (#6 in the picture) and a new rubber boot (#14 in the picture) (click to enlarge)